Page 1 of 1

Thanks Duane...

Posted: Mon Jan 09, 2012 4:36 pm

by dougie

As I have always been judicious about using copper anti-seize on my exhaust nuts, I was surprised when one of them bound up after a half turn.

I did it back up and tried again - no go.

Tried a few times with more grunt and heard Duane's voice saying "Cut it off!"

Gave myself a dope slap, walked away, muttered profanities, and came back with a Dremel.

Cut a section out, stretched the remainder, and off it came.

The spigot and nut had been exchanging aluminium in a few spots. The worst bit I carefully cleaned up with a triangular file until I could get the new nut started.

I then did the fine grinding paste treatment and that took patience. It worked so well that I also did the other cylinder which had a couple of notchy spots.

After a

thorough cleaning and a bunch of anti-seize both sides tightened up nicely and I am probably good to go.

Good tricks Duane - thanks.

exhaust nut 002.jpg

Re: Thanks Duane...

Posted: Mon Jan 09, 2012 6:05 pm

by Garnet

Not just another pretty face, eh? (or hungh, for my Mercan freinds.

)

Re: Thanks Duane...

Posted: Mon Jan 09, 2012 6:34 pm

by DanielMc

My experience with marine engineering has left me with a real distrust of any situation that puts copper and aluminium together in the presence of an electrolyte.I know people claim that copper grease is fine on airhead exhaust threads, but if the grease dries out and salt water gets in you've actually made a nice little electrolytic experiment that turns exhaust threads into aluminium oxide.

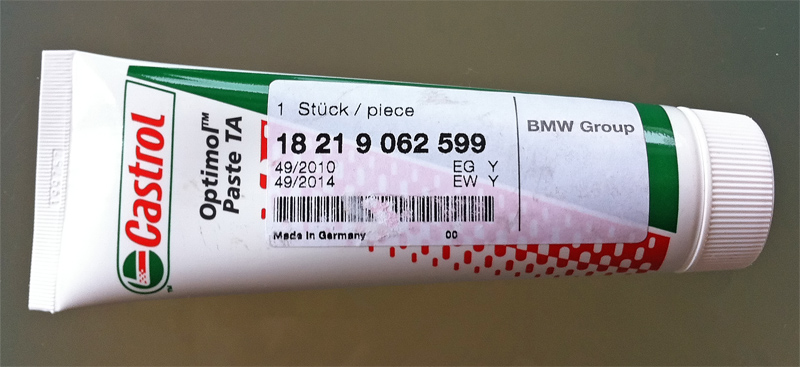

BMW themselves recommend Optimol TA paste, and I've been using this on exhaust threads (and any exhaust pipe joins) for years with no problems whatsoever:

Optimol Paste TA for screw connections up to 1100ºC. It is used as assembly paste and prevents seizing, welding or scaling. Optimol Paste TA ensures a good separating and sealing effect in high temperature and wet environments as well as under the influence of aggressive media.

Re: Thanks Duane...

Posted: Mon Jan 09, 2012 9:46 pm

by Duane Ausherman

dougie, thanks for the kind words. I can't recall a single case where we used the paste and it later was stuck. However, we certainly did cut a lot of them off as they came from BMW.

I would not recommend using the copper paste in this application. I use some older aluminum/silver color stuff and it seems to work OK.

I do use the copper paste when I crimp a copper lug to copper wire. I also use the copper when attaching a cad or copper lug to a copper buss bar. Some of those have very high current flowing through them. We never have trouble getting them off, just need to keep the resistance very low to preserve energy and keep the heat down.

Re: Thanks Duane...

Posted: Tue Jan 10, 2012 6:15 am

by hal

Are you saying I should use copper paste instead of vaseline (which I'm now using) before crimpin on spades to cables?

I understand this is part of your current profesion

Re: Thanks Duane...

Posted: Tue Jan 10, 2012 1:05 pm

by Duane Ausherman

NO, to use copper paste with any metal other than copper may be a problem later on. Vasoline may be ok too, but it may have some additives that could affect some types of metal. I prefer one of the many products that are made for this application. We typically refer to them as NO-OX.

If you don't have NO-OX, then use the Vasoline, as it is better than allowing in air that contains humidity.

Yes, I work in telecom now and on the wireless side. The copper wired side (standard house phone technology) uses even larger copper cables in the switches and those folks really do know the business. On the wireless side we use cables in cell sites that usually don't exceed 4-0.

The whole idea is to keep ambient air out of the crimp. Crimping is a whole technology by itself and very few do it correctly. When I find installers at a cell site doing power work, I always casually watch them crimp. Few have a clue and weren't trained correctly, or at all. That is why we have a 200-300% safety factor designed in. Still, I sometimes go over, by hand, the connections and find some of them to be hot to the touch. Many of the contract workers have learned to fear/hate me. It only takes a few more seconds to do the job correctly, so why not do what you are paid for?

Re: Thanks Duane...

Posted: Wed Jan 11, 2012 8:23 am

by ME 109

I've found the best anti seize to be constant removal of the exhaust system.......

Re: Thanks Duane...

Posted: Wed Jan 11, 2012 10:00 am

by DanielMc

ME 109 wrote:I've found the best anti seize to be constant

removal reattaching of the exhaust system.......

Fixed to reflect Australian riding conditions...