Page 1 of 1

engine clean up

Posted: Mon Jul 07, 2014 7:31 pm

by oldRNineTguy

I recall that GSPD some time ago published his technique for keeping his engine clean looking. From the pics of his ride then, it was a workable system. It was a lengthy tome; did anyone here save it? If so let me know and I'll contact you to get a copy of it.

Re: engine clean up

Posted: Mon Jul 07, 2014 8:11 pm

by dwerbil

Ya...copy and paste it here.

Here's a thread with a bit about it. Looks like the "gspd method" is from the old-old forum. (gone)

Maybe SteveD has it on file....

viewtopic.php?f=1&t=4398

Re: engine clean up

Posted: Mon Jul 07, 2014 9:29 pm

by SteveD

I've looked thru my files, but can't find it.

From memory GSPD sparsely sprayed his aluminium coloured paint onto a rag and massaged it onto whatever it was he was tidying up. He made the point to rub it on, not to spray then spread.

Melville is the one that has used his technique extensively I think.

Re: engine clean up

Posted: Mon Jul 07, 2014 10:13 pm

by melville

A soft ScotchBrite pad is the applicator. It gets the paint into the pores and should stop corrosion starting in the pores. I used Duplicolor 'Cast Aluminum' paint from my FLAPS. Shake it up, spray it on the SB, and rub it in until there are no streaks.

The work is in cleaning up the crusty parts to begin with. I used #2 steel wool on the worst of the parts. Most of the process posts were lost with the 'old' (not 'old-old') board four years ago. My build thread has a few 'spring refresher' posts on how easy it is to maintain that finish on an annual basis.

Here's my build thread:

viewtopic.php?f=1&t=148&hilit=woo+hoo

And directly to a 'spring refresher' post:

viewtopic.php?f=1&t=148&hilit=woo+hoo&start=320

Re: engine clean up

Posted: Wed Aug 27, 2014 11:05 am

by loowiloowi

I just cleaned up all of the cast on a 76 R90/6. I started using 000 steel wool by hand but found that it was really slow and I was concerned that the microscopic left overs would tend to rust when the bike was washed or ridden in the rain.... I then changed to the red Scotch Brite pads and it was still slow but the concern of rust was gone. I then took a pad of SB and punched ~ 1.5" circles out of it. I then poked a very small hole in the center and mounted it to a Dremel mandrel with a small washer on each side, voila the work went much faster and I was able to get between the spokes of the hub to do a great job of cleaning the hubs. They don't last very long so make at least 12 circles for 2 wheel hubs, maybe more. That's my story and I'm sticking to it........ Oh some fastener stores have 10" X 12" pads available for much less than your local hardware store sells the 4" X 12" pads.....

Re: engine clean up

Posted: Wed Aug 27, 2014 1:01 pm

by barryh

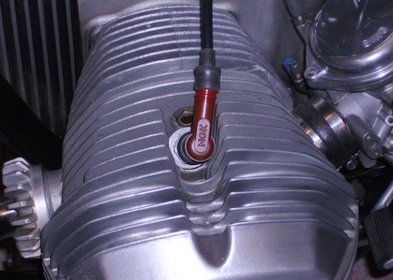

You mean like this. Home made variety on the right for cleaning between the fins.

...and the result. Not as good as blasting but not bad.

Re: engine clean up

Posted: Thu Aug 28, 2014 2:26 am

by Duane Ausherman

melville wrote:A soft ScotchBrite pad is the applicator. It gets the paint into the pores and should stop corrosion starting in the pores. I used Duplicolor 'Cast Aluminum' paint from my FLAPS. Shake it up, spray it on the SB, and rub it in until there are no streaks.

The work is in cleaning up the crusty parts to begin with. I used #2 steel wool on the worst of the parts. Most of the process posts were lost with the 'old' (not 'old-old') board four years ago. My build thread has a few 'spring refresher' posts on how easy it is to maintain that finish on an annual basis.

Here's my build thread:

viewtopic.php?f=1&t=148&hilit=woo+hoo

And directly to a 'spring refresher' post:

viewtopic.php?f=1&t=148&hilit=woo+hoo&start=320

When you test rode it, did it track in a straight line? Your string method was true within 1/32" and I just would like to know how accurately it turned out.

Re: engine clean up

Posted: Thu Aug 28, 2014 7:15 am

by melville

Duane Ausherman wrote:melville wrote:A soft ScotchBrite pad is the applicator. It gets the paint into the pores and should stop corrosion starting in the pores. I used Duplicolor 'Cast Aluminum' paint from my FLAPS. Shake it up, spray it on the SB, and rub it in until there are no streaks.

The work is in cleaning up the crusty parts to begin with. I used #2 steel wool on the worst of the parts. Most of the process posts were lost with the 'old' (not 'old-old') board four years ago. My build thread has a few 'spring refresher' posts on how easy it is to maintain that finish on an annual basis.

Here's my build thread:

viewtopic.php?f=1&t=148&hilit=woo+hoo

And directly to a 'spring refresher' post:

viewtopic.php?f=1&t=148&hilit=woo+hoo&start=320

When you test rode it, did it track in a straight line? Your string method was true within 1/32" and I just would like to know how accurately it turned out.

Rode it no hands yesterday. Just like a good bicycle.

Re: engine clean up

Posted: Thu Aug 28, 2014 2:32 pm

by Major Softie

melville wrote:

Rode it no hands yesterday. Just like a good bicycle.

I can ride a motorcycle straight with no hands even if it doesn't track straight . . . of course it looks a little silly with me trying to hang that far off to the side with no hands.